Digital Transformation in Manufacturing: Challenges & Madasky Consulting's Approach

Image

ImageThe manufacturing sector is undergoing a paradigm shift with digital transformation, but the journey is fraught with challenges. Some of the major hurdles include:

Legacy Systems & Integration Issues: Outdated infrastructure that lacks interoperability with modern digital tools.

High Implementation Costs: The initial investment in technology, software, and infrastructure can be substantial.

Workforce Resistance & Skills Gap: Employees often resist change due to a lack of digital skills and fear of automation replacing jobs.

Cybersecurity & Data Privacy Concerns: Increased connectivity exposes businesses to cyber threats and data breaches.

Data Management & Utilization: Manufacturing companies generate vast amounts of data but struggle to derive actionable insights.

Operational Downtime Risks: Transitioning to digital solutions can temporarily disrupt production, impacting efficiency.

Image

ImageScalability & Flexibility: Digital transformation should be scalable to accommodate growth without overhauling the entire system.

Customer Experience & Market Demands: Meeting evolving customer expectations with personalized and data-driven solutions.

Image

ImageAt Madasky Consulting, we provide a structured and scalable digital transformation framework that enables manufacturers to overcome these challenges and stay ahead in a competitive landscape.

Strategy & Advisory

Digital Strategy Development: We align business goals with digital transformation initiatives to create a clear roadmap.

Change Management & Digital Adoption: Our expertise ensures a smooth transition to new digital processes with minimal disruption.

Data & Analytics

Big Data & Advanced Analytics: We leverage AI and ML to derive actionable insights from data, improving decision-making.

Business Intelligence (BI) & Visualization: Utilizing Power BI, Tableau, and Looker to provide real-time business insights.

AI & Automation

Artificial Intelligence & Machine Learning (AI/ML): Automating complex decision-making processes to enhance efficiency.

Implementing bots to streamline repetitive and manual tasks.

Image

ImageIndustry Expertise: With deep experience in manufacturing and digital transformation, we understand industry-specific challenges and provide tailored solutions.

Proven Track Record: Successfully enabling businesses to adopt cutting-edge digital solutions that drive efficiency and growth.

Holistic Approach: From strategy and implementation to training and scaling, we ensure a seamless digital transformation journey.

Technology Partnerships: Collaborating with leading tech providers for AI, IoT, automation, and cloud solutions.

End-to-End Support: We guide businesses at every step, ensuring minimal disruption and maximum ROI.

Image

ImageAt Madasky Consulting, we empower manufacturers to scale, grow, and thrive in the new age of digital transformation. Contact us today to embark on your digital journey!

In today's fast-paced manufacturing world, efficiency, precision, and real-time decision-making are crucial for success. Yet, many manufacturers struggle with outdated processes, unplanned downtime, and a lack of real-time visibility. Manual tracking, paper-based documentation, and siloed data lead to delays, inefficiencies, and rising costs. Without centralized insights, identifying bottlenecks, optimizing workflows, and ensuring consistent product quality becomes a challenge.

As competition intensifies and operational costs rise, manufacturers must embrace digital transformation to stay ahead. Smart tracking systems, AI-driven analytics, and automated dashboards can revolutionize production, boosting efficiency and reducing waste. Our consulting firm specializes in implementing tailored digital solutions that enhance productivity, streamline operations, and drive long-term growth. Below, we explore key industry challenges and how our expertise can help solve them.

Image

ImageManufacturers operating without digital tools face several critical inefficiencies that impact productivity, costs, and overall competitiveness. Some of the key challenges include:

Unplanned Downtime & Frequent Breakdowns: Lack of predictive maintenance leads to unexpected machine failures, causing costly production halts and delays.

Intelligent Process Automation (IPA): Integrating AI, RPA, and analytics to create intelligent workflows and improve productivity.

Image

ImageCustomer Experience & Digital Marketing

Customer Relationship Management (CRM): Enhancing customer engagement through platforms like Salesforce and HubSpot.

Omnichannel Experience: Ensuring seamless integration between digital and physical customer interactions.

MarTech & Digital Marketing Solutions: Implementing AI-driven marketing automation tools for targeted campaigns.

Industry-Specific Digital Solutions

Manufacturing (Industry 4.0): Implementing IoT, smart factories, and predictive maintenance to enhance production efficiency.

Retail & E-Commerce: AI-driven personalization, chatbots, and advanced digital payment solutions.

Product & Service Innovation

Agile & DevOps Enablement: Accelerating software development with agile methodologies and DevOps practices.

Digital Twin & Simulation: Creating digital replicas of physical systems for process optimization and efficiency.

IoT & Edge Computing: Leveraging real-time data from connected devices for predictive analytics and automation.

Product & Service Innovation

Agile & DevOps Enablement: Accelerating software development with agile methodologies and DevOps practices.

Digital Twin & Simulation: Creating digital replicas of physical systems for process optimization and efficiency.

IoT & Edge Computing: Leveraging real-time data from connected devices for predictive analytics and automation.

Workforce & Collaboration Solutions

Digital Workplace Transformation: Implementing remote collaboration tools such as Microsoft 365, Slack, and Zoom.

Employee Experience Platforms (EXP): Enhancing workforce engagement with AI-powered HR solutions.

Training & Upskilling Programs: AI-driven learning platforms for continuous workforce development and digital readiness.

Limited Visibility & Data Silos: Without real-time tracking, floor managers rely on outdated reports, making it difficult to monitor production progress and react swiftly to issues.

High Work-in-Progress (WIP) & Bottlenecks: Inefficient workflow tracking results in excessive WIP, increasing lead times and creating bottlenecks that slow down output.

Manual Tracking & Paper-Based Processes: Dependence on spreadsheets and physical documents increases errors, slows decision-making, and limits process transparency.

Image

ImageInconsistent Product Quality & High Rejection Rates: Without automated quality monitoring, defects go unnoticed until the final inspection, leading to rework, material wastage, and customer dissatisfaction.

Inefficient Resource Utilization: Poor workforce allocation and lack of real-time machine monitoring result in idle time, low productivity, and increased labor costs.

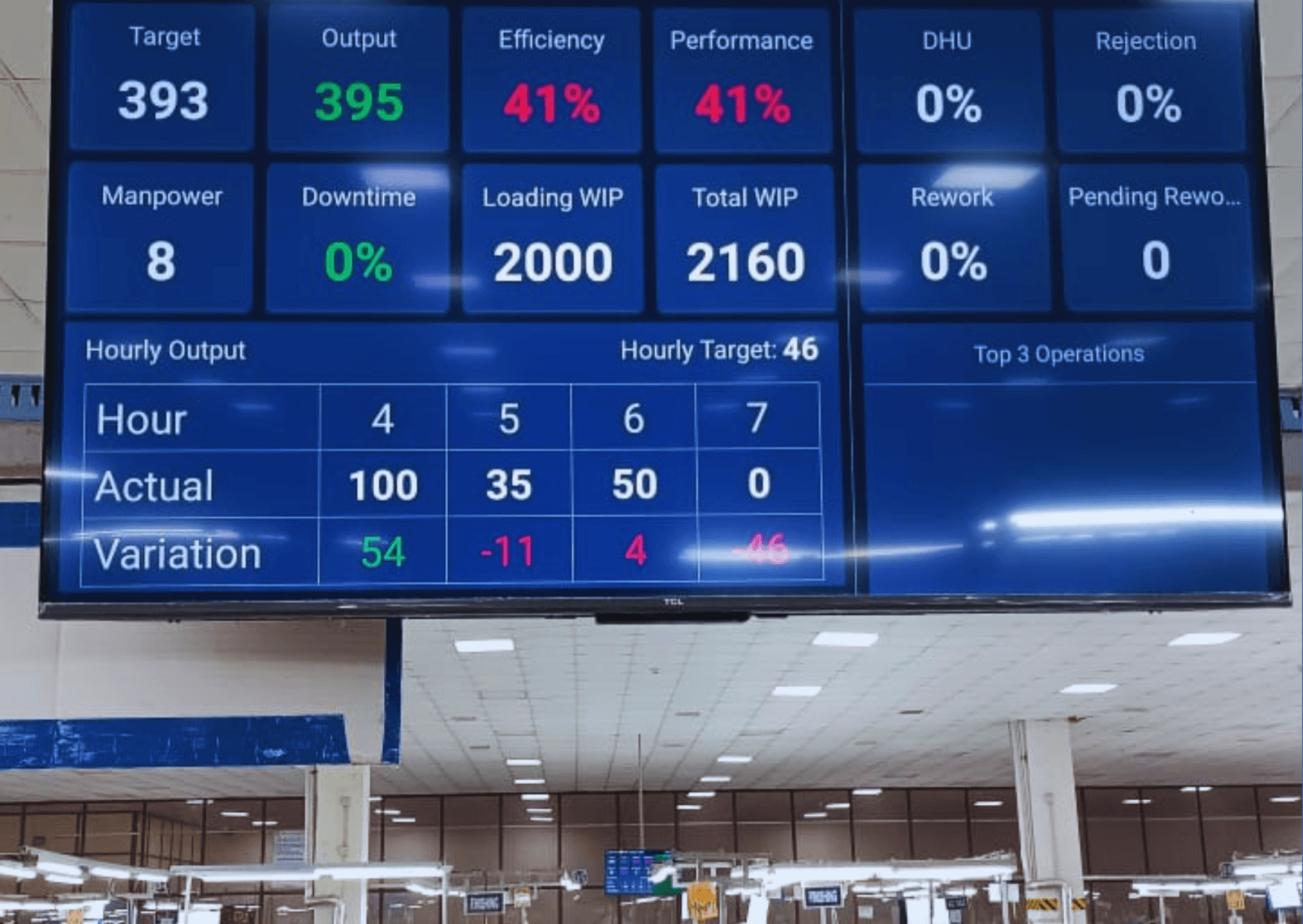

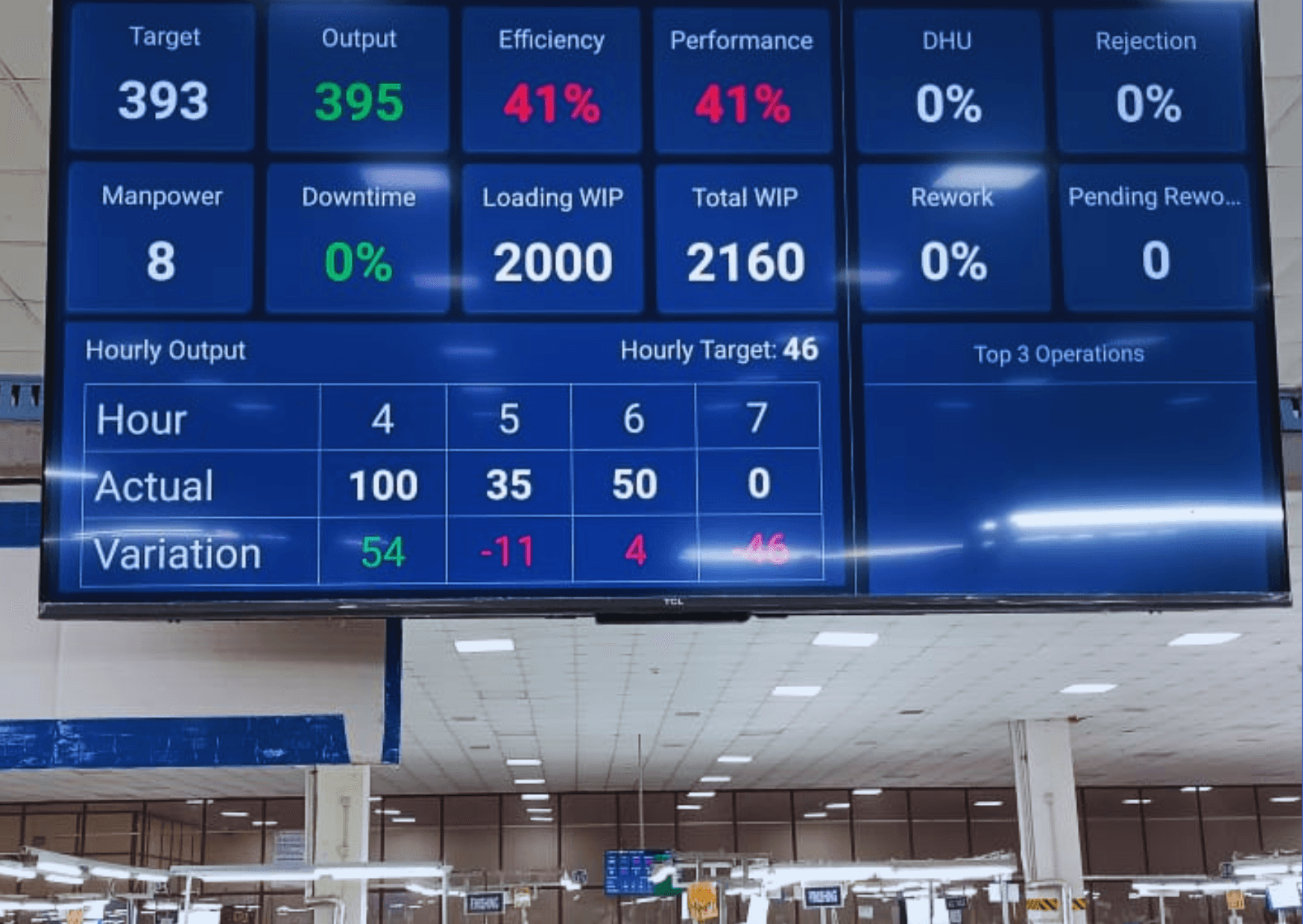

Lack of Real-Time Performance Monitoring: Managers cannot track efficiency, production rates, or deviations in real-time, leading to delayed corrective actions and missed improvement opportunities.

Difficulty in Scaling & Adapting to Market Demands: Inflexible production processes make it harder to scale operations, introduce new products, or adapt to changing customer demands.

Image

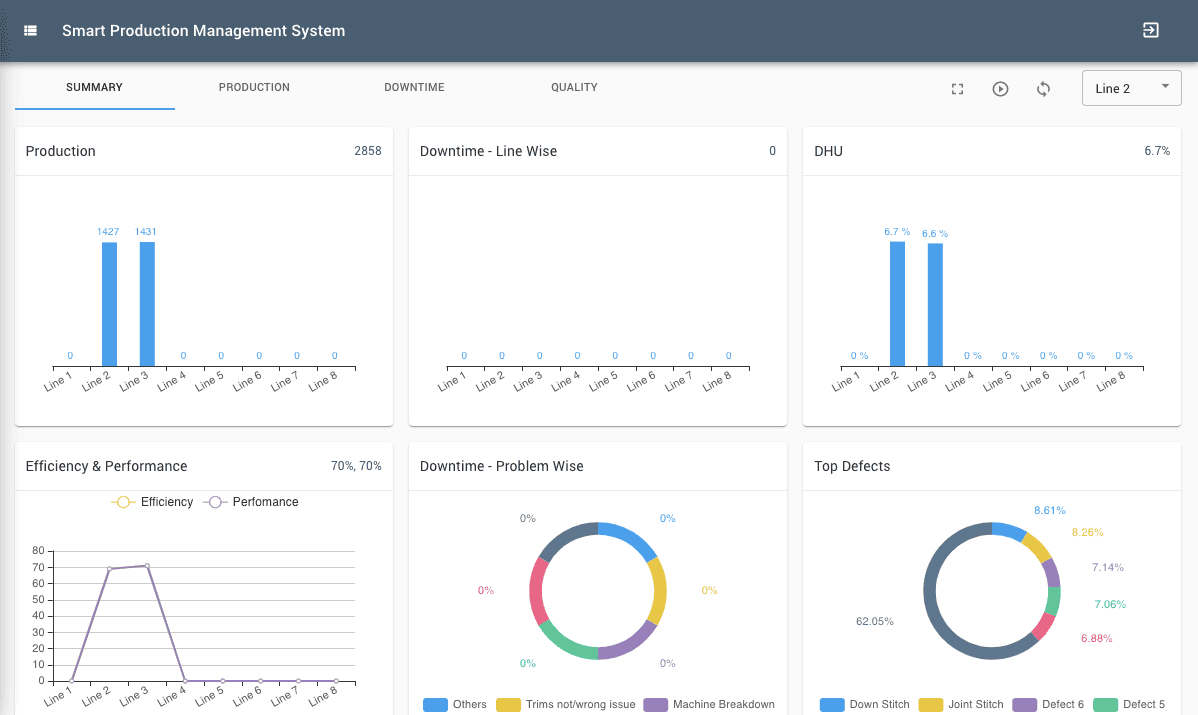

ImageReal-Time Production Tracking: Gain complete visibility into your production floor with real-time monitoring of machine operations, process stages, and performance metrics.

Downtime & Efficiency Monitoring: Identify and analyze operational bottlenecks, enabling predictive maintenance and reducing unplanned downtime.

First-Hour Production Optimization: Monitor the initial output of each shift to detect inefficiencies early and set the foundation for peak productivity.

AI-Driven Production Dashboards: Live dashboards display key performance indicators (KPIs), alerting managers to maintenance needs, production trends, and efficiency gaps.

Image

ImageDigital Workflows & Paperless Operations: Eliminate manual paperwork by transitioning to digital workflows, ensuring seamless data integration across departments.

Process Automation & Smart Scheduling: Automate repetitive tasks and optimize scheduling with AI-powered insights, reducing dependency on manual interventions.

Quality Control & Predictive Analytics: Use AI-driven quality control measures and predictive analytics to minimize defects, ensuring consistent product excellence.

Workforce Digital Enablement: Equip employees with intuitive digital tools and training to enhance operator performance and productivity.

Complete Factory Visibility & Traceability: Ensure end-to-end traceability of every production process, enabling better compliance, accountability, and data-driven decision-making.

Scalable & Future-Ready Operations: Implement flexible digital solutions that adapt to business growth, allowing seamless expansion without operational disruption.

20% Efficiency Gains: Optimize workflows and reduce waste.

25% Reduction in Operating Costs: Lower expenses through automation and predictive maintenance.

35% Revenue Growth: Enhance output and market responsiveness.

100% Shop Floor Visibility: Gain real-time insights for proactive decision-making.

Unmatched Product Quality: Achieve consistency with AI-driven quality controls.

Go Fully Paperless: Streamline documentation and eliminate manual data entry.

At Madasky Consulting, we understand that every industry has unique challenges and requirements. To address these, we have partnered with leading IT companies to provide tailored digital solutions that align with the specific needs of our clients across various sectors. Our collaborative approach ensures that our clients receive the most advanced and effective tools to enhance their operations, drive innovation, and achieve sustainable growth.

Image

ImageIn today's fast-paced manufacturing world, efficiency, precision, and real-time decision-making are crucial for success. Yet, many manufacturers struggle with outdated processes, unplanned downtime, and a lack of real-time visibility. Manual tracking, paper-based documentation, and siloed data lead to delays, inefficiencies, and rising costs. Without centralized insights, identifying bottlenecks, optimizing workflows, and ensuring consistent product quality becomes a challenge.

In today's fast-paced manufacturing world, efficiency, precision, and real-time decision-making are crucial for success. Yet, many manufacturers struggle with outdated processes, unplanned downtime, and a lack of real-time visibility. Manual tracking, paper-based documentation, and siloed data lead to delays, inefficiencies, and rising costs. Without centralized insights, identifying bottlenecks, optimizing workflows, and ensuring consistent product quality becomes a challenge.

In today's fast-paced manufacturing world, efficiency, precision, and real-time decision-making are crucial for success. Yet, many manufacturers struggle with outdated processes, unplanned downtime, and a lack of real-time visibility. Manual tracking, paper-based documentation, and siloed data lead to delays, inefficiencies, and rising costs. Without centralized insights, identifying bottlenecks, optimizing workflows, and ensuring consistent product quality becomes a challenge.